Monolithic Dome Airform and Fabric Product Manufacturing

The giant 182-foot diameter Monolithic Dome Airform dwarfs the surrounding construction equipment on a frosty winter evening in Alberta, Canada. This is the largest transverse Airform built to date. Monolithic was granted a patent for this ingenious new patterning technology which creates more streamlined, elegant Airforms.

Andrew South

Monolithic Airform Manufacturing has built hundreds of Monolithic Dome Airforms for domes in all 50 states and dozens of countries—from the Arctic to the tropics.

We combine modern patterning, cutting and fabric welding technologies with creative and intelligent design. We find real-world solutions to achieve complex architectural ideas and site requirements. In building more Monolithic Dome Airforms than any other company — and because of ongoing testing and research —we have continually improved the quality of Monolithic Airforms and innovated new methods for their fabrication. An example of this is the new Transverse Airform, developed here at the Monolithic Research and Industrial Park in Italy, Texas.

We construct a wide variety of fabric structures.

Monolithic’s Airform Manufacturing constructed this cover for a waste treatment system—a methane digester. This commercial textile product is made of heavy 31-ounce fabric, and custom fitted to existing waste digestion tanks.

We have always made more than just Monolithic Dome Airforms in our very busy caterpillar-shaped manufacturing plant. We have built hundreds of methane digester covers, condensate ceilings, compost covers, tension structures, grain covers, athletic tents and more.

In fact, Monolithic can design and construct virtually any fabric form. Event planners, playground and park designers, athletic directors, fracking companies, wastewater treatment plants, agricultural research and development organizations and many more groups and people use architectural textiles. We can help any of these groups achieve their goals. We partner with customers to develop prototypes or go directly to mass-producing custom fabric forms. We provide innovation and creativity — along with cutting-edge tech — in an approachable and dependable way.

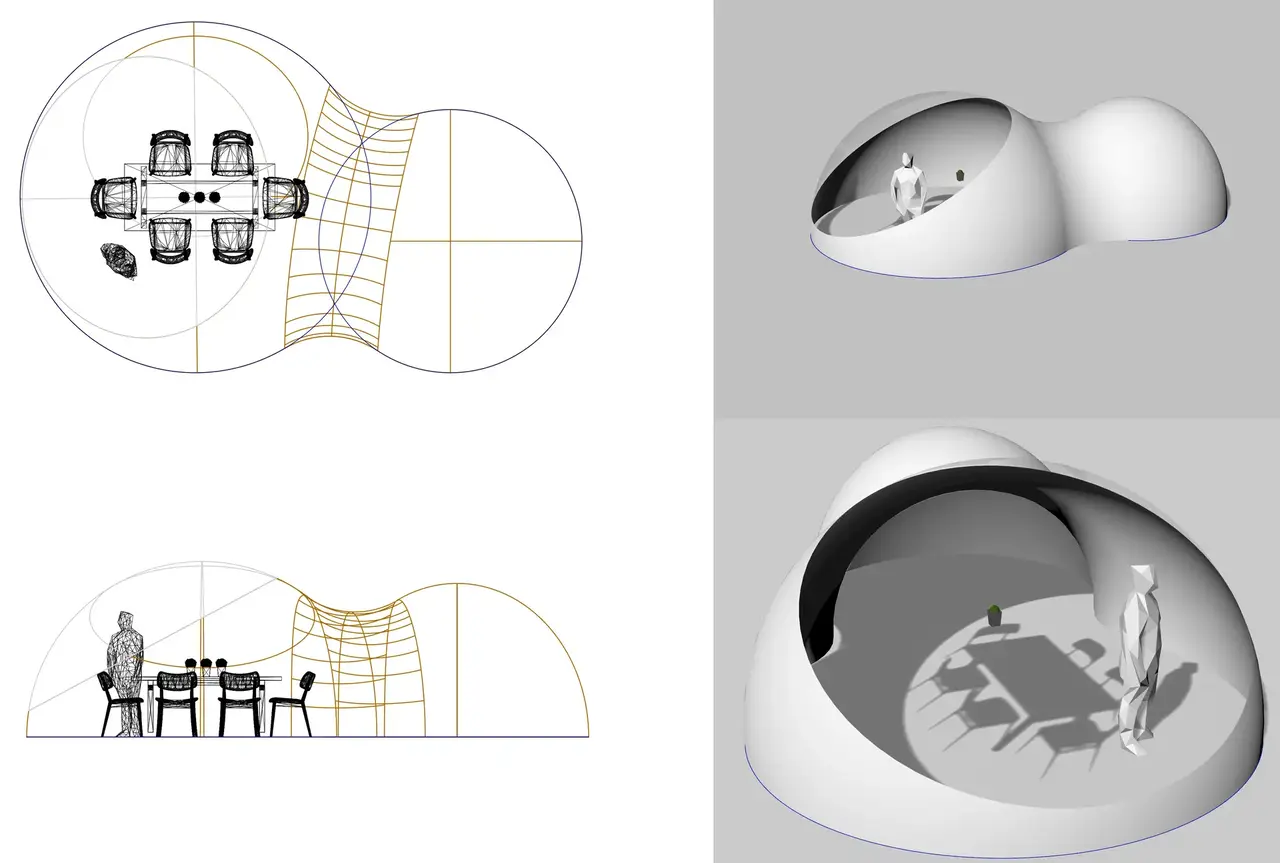

This inflatable fabric tent could be a temporary conference room at an expo or house a popup shop or restaurant. A few of these structures grouped together would create an excellent glamping site or guest quarters for a family reunion. Just a small fan and manometer are required to keep this textile product inflated. Note: We are not limited to round structures. Monolithic can fabricate any shape for a tent or seasonal shelter.

We are based in Texas — An advantage to the customer.

Instead of outsourcing to another country overseas to have a custom textile product constructed, our manufacturing plant is located right here in Italy, Texas.

We have the experience and cutting-edge textile manufacturing tools.

Our 14,000 square foot plant houses a state-of-the-art, laser-guided, 200-foot long RF welder that heats and seals fabric pieces together using high-frequency electromagnetic energy.

Inside Monolithic’s manufacturing facility where we construct Airforms and other specialty textile products and fabric forms. The caterpillar-shaped building is composed of 7, 60-foot diameter, interconnected domes. Inside are 14,000 square feet of factory space and a 200-foot-long automated, laser-guided RF welder.

Mike and Dave South have 50 years’ worth of combined experience pioneering some of the world’s most complicated fabric form architecture. Yet, we are a small enough company to give each one of our customers our full attention. We work best when our customers are our partners — working toward their project’s success.

Examples of fabric forms we design and manufacture:

- Condensate ceilings for water towers

- Specialty tents for any event or permanent structure

- Grain covers

- Custom air structures for tennis tournaments or temporary indoor arenas

- Methane

- Fabric water tanks

- Compost covers

- Airformed Culverts

- Airformed concrete tunnels and pipes

- High quality, heavy-duty custom equipment tarps and everything else