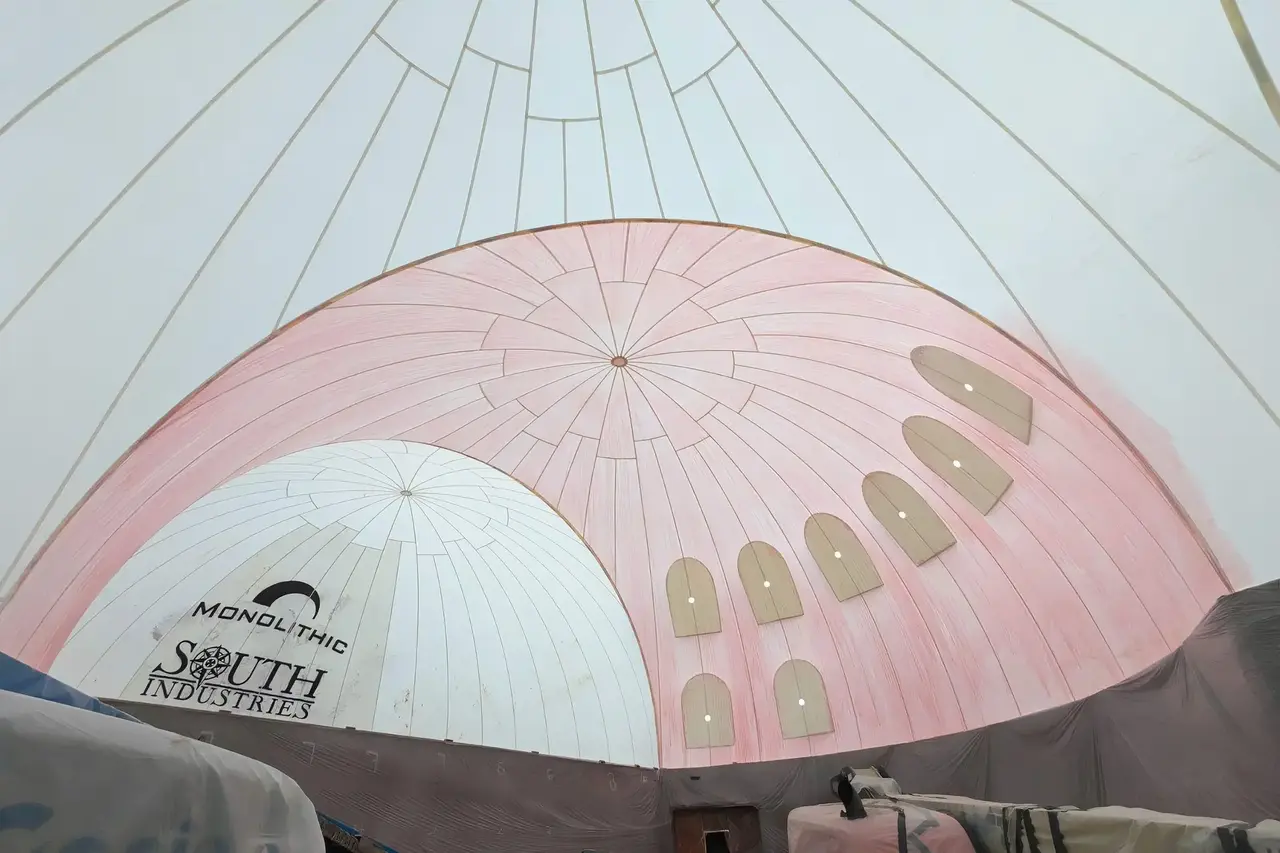

Inflation of Unique Airform for Clubhouse in Virginia

The Airform was designed and manufactured at Monolithic for this clubhouse, which has six 60-foot-diameter interconnected domes.

Mike South / Monolithic Commons / CC BY-SA 4.0

In February, we started the patterning and manufacturing of one of our most unique projects for 2024. This Airform is for a clubhouse being built in Virginia. It is made up of six interconnected, 60-foot (12 m) diameter domes. Three domes will have massive cutouts in which glass walls will be installed. The many augmentations on the first and second floors and all the connections between the six large domes made it a fun and complicated fabric architecture project.

The window augments are manufactured with a fabric panel in front of them to help keep their shape until the first layers of foam are applied. Actually, we use several techniques, like temporary interior framing and exterior straps, to ensure that the Airforms keep their shape during the early stages of construction.

Seeing the inflated Airforms before construction goes forward and foam is sprayed on their interiors has always been a favorite part of the process for me. The patterns of the seams we created during the design phase always look incredible when the fans are turned on, and the Airforms are ultimately inflated.

Taken when the Airform was initially inflated at low pressure, this image shows off the dramatic double-curve arches created between domes with this type of soap-bubble connection.

Mike South / Monolithic Commons / CC BY-SA 4.0

The red color of the center dome is due to the application of MonoForm primer, which we manufacture. MonoForm helps the adhesion of polyurethane foam to the Airform. It also mitigates plasticizer migration from the PVC in the Airform material.

Mike South / Mike South / CC BY-SA 4.0

Designing and building Airforms for the construction of Monolithic Domes is a specialty of Monolithic. Our Fabric Architecture Manufacturing division can fabricate almost anything, from tents and inflatables to industrial tarps and methane recovery systems.

Mike South / Monolithic Commons / CC BY-SA 4.0

The Airform for the large clubhouse is on the trailer, leaving Monolithic’s factory in Italy, Texas. That tiny package will be inflated into a huge structure.

Mike South / Monolithic Commons / CC BY-SA 4.0

The Airform is inflated at low pressure in this image. The lights from inside make it glow, creating some unique exterior shots.

Mike South / Monolithic Commons / CC BY-SA 4.0